Electromigration Testing System

| Capacity | 60 DUTs (20DUTs / 3 ovens) |

| Temerature | 350 °C |

| Max. Current | 20mA / 80mA |

| Source Resolution | 1mA / 10mA |

| Vendor | Qualitau |

| Characteristics | Independent temperature control of ovens available |

TDDB Testing System

| Capacity | 20DUTs |

| Temerature | 350 °C |

| Max. Voltage | 100 V |

| Source Resolution | 160 mV |

| measure Accuracy | 0.1% |

| Puls mode | AC / DC pulse |

Glove Box

| Box Size | 1725(W)x760(D)x890(H)mm |

| Chamber Vacuum | 10-3 torr |

| Moisture removal | Less than 1 PPM |

| Oxigen removal | Less than 1 PPM |

| Blow speed control | Max. 63. cfm |

| Vacuum Pump | 200. Ll/min |

RF Sputter System

| Vacuum level | 3×10-7 torr |

| Power | Max. 645W |

| Process Gas | Ar, O2 |

| Sample type | 4″ wafer |

| Target. Materials | IGZO, Mo, Ti, Cu |

| Etc | Gun 3EA(RF 2EA, DC 1EA) Co-deposition Available |

UHV Sputter System

| Vacuum level | 3×10-10 torr |

| Power | Max. 1kW |

| Process Gas | Ar, N2 |

| Sample type | 4″ wafer, Sample(2cmX2cm) |

| Target. Materials | Cu and alloy(Cu-Mg,Cu-Ru) AI and alloy(AI-No,AI-Sc) |

| Etc | Gun 3EA |

HV Sputter System

| Vacuum level | 3×10-7 torr |

| Power | Max. 600W |

| Process Gas | Ar, N2 |

| Sample type | 4″ wafer, Sample(1″x1″) |

| Target. Materials | Ta, Cr, AI, Cu |

| Etc | Gun 3 EA |

Thermal Evaporator

| Use | Film deposition |

| Vacuum level | 10 x 10-7 Torr |

| Voltage | Max. 200V |

| Process. Gas | N2 |

| Sample type | 4″ safer |

| Target materialls | Sn, Ag, AI, Cu, etc |

| Etc | 2 Boats |

MOS Multi-beam Optical System

| Use | In-situ stress measurement of thin films |

| Available curvature | ~. 10km (approx.) |

| Temperature | RT ~ 300ºC |

| Vacuum | ~ 10-6 Torr |

| Vendor | K-Space Associates(USA) |

Micro Tensile Tester

| Test force | 0 ~ ± 500 N |

| Load cell | ± 500 N |

| Piston stoke | Max. ± 10 mm |

| Frequency | Max. 100Hz |

| Test application | Tensile & fatique test, 3 point bending test, 4. point bending test |

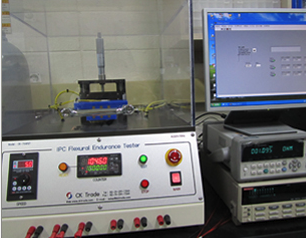

Bending Fatigue Testing System

| Appliable Stress | Tensile bending, Compressive bending |

| Sliding Distance | 5, 10, 15, 20 mm |

| Gap | 0 ~ 50 mm |

| Moving Frequency | 0 ~ 5 Hz |

Electromigration Testing System

| Current Source | Max. 5A DC / 1~10 Hz Pulse DC |

| Measure method | 2. wire & 4 wire resistance measure (Measure. accuracy 1mΩ) |

| Test Temp | Max. 350ºC |

| Testing DUT | 8ea for DC 1 set 4ea for pulse DC 2 set |

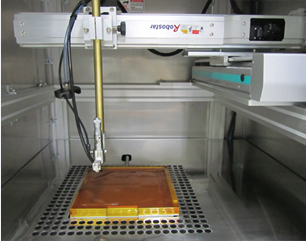

Spray Coater

| Liquid spray volume range | 0. ~ 10 ml/min |

| Necessary gas volume range | 2 ~ 12 L/min |

| Spray Area | 200 mm x 200 mm |

| Spray Volume | 1 ml/min ~ 10ml/min |

| Heater Unit | Max. 300ºC |

| Etc | Spray X,Y reobot system, Heating& sunction unit |

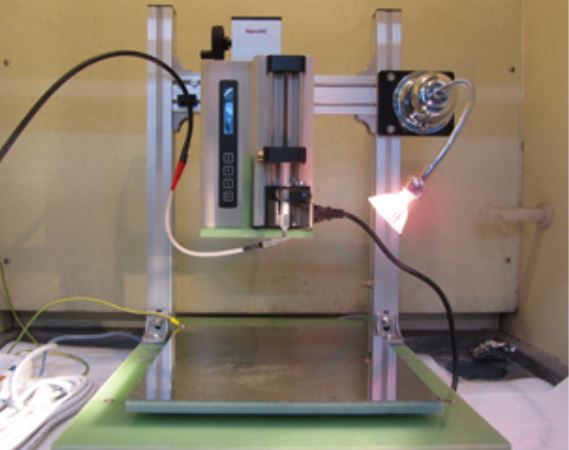

Electrospinning Equipment

| Precision fluid metering pump | syringe size: 10 µl ~ 60 ml Flow rate : 0.21 µl/hr |

| High voltage generator | 30kV / 2mA |

| Flat collector | 300 mm x 300 mm |

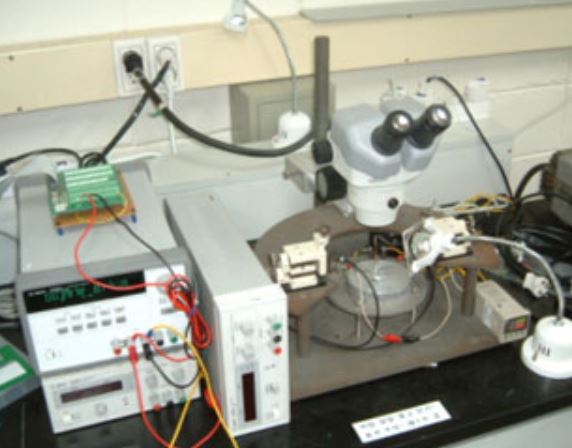

Vacuum Probe Station

| Use | Electric characteristics or reliability test at various atmosphere(N2,H2, Vacuum) |

| Vacuum level | 3 x 10-6 Torr |

| Temperature | Max. 300ºC |

| Source Voltage | Max. 60 V |

Multi Probe Station for TDDB

| Use | TDDB test |

| Temperature | Max. 400 ºC |

| DC output | 100 fA ~ 10µA |

| Resolution | Max. 150 V (step: 100mV, Accuracy:±(0.04%+240 mV)) |

| Stability | 100 mV (Accuracy:±(0.035%+100 mV)) |

| Etc | Concidence measurement of 10 samples availiable |

RF Probe station

| 8 inch wafer | |

| Vacuum chunk | |

| X/Y/Z manual control | |

| DC to 40 GHz microwave support | |

| RF manipulator and probe tip |

RF Measure System

| Pulse generator | Frequency range 1mHz~165MHz Amplitude range 100mV ~ 3.8V Source impedance 50Ω ~ 1kΩ |

| Oscilloscope | 1GHz bandwidth Up to 4GSa/s sample rate |

| RF switching matrix system | Up to 2GHz |

| Pico ammeter |

Wafer Level Reliability Analyzer

| Use | Electro Measurement |

| Temperature | 300 ºC |

| DC output | 0 ~ 15V/7A, 0 ~ 30V/4A |

| Resolution | Program: 1mV/0.5mA, Meter: 1mV/1mA |

| Stability | Voltage:0.02% + 1mA Current: 0.1% + 1mA |

| Etc | Microprobe |

Reliability Testing Chamber

| Use | PCB ion migration |

| Temp. | -2- ~ 200 ºC (variation±0.2ºC, uniformity ±0.75ºC) |

| Humidity | 25 ~ 98 % (variation±0.5ºC, uniformity ±0.25ºC) |

| Current | 10 pA ~ 1 A |

| Voltage | 1 µV ~ 200 V |

HV Furnace

| Vacuum level | 10 x 10-7 Torr |

| Use | Heat treatment |

| Process Gas | O2, N2 |

| Sample type | Piece-like sample |

| Characteristic | Fast heat treatment available |

| Temperature | 1000 ºC |

Forced Convection Dry Oven

| Use | Super High Temp. Dry Oven |

| Power | 220 V (60 Hz, 2100 W) |

| Temp. | AMB ±0.5ºC to 350ºC (500ºC) |

| Time | 00.00 to 99 hr 59 min/min. Sec free selectable |

| Characteristic | Reliability test of Packaging sample |

Optical Microscope

| Use | Analyzing microstructure |

| Magnification | Max. x1000 |

| Resolution | 1 pA ~ 10A |

| Voltage | 1000 V |