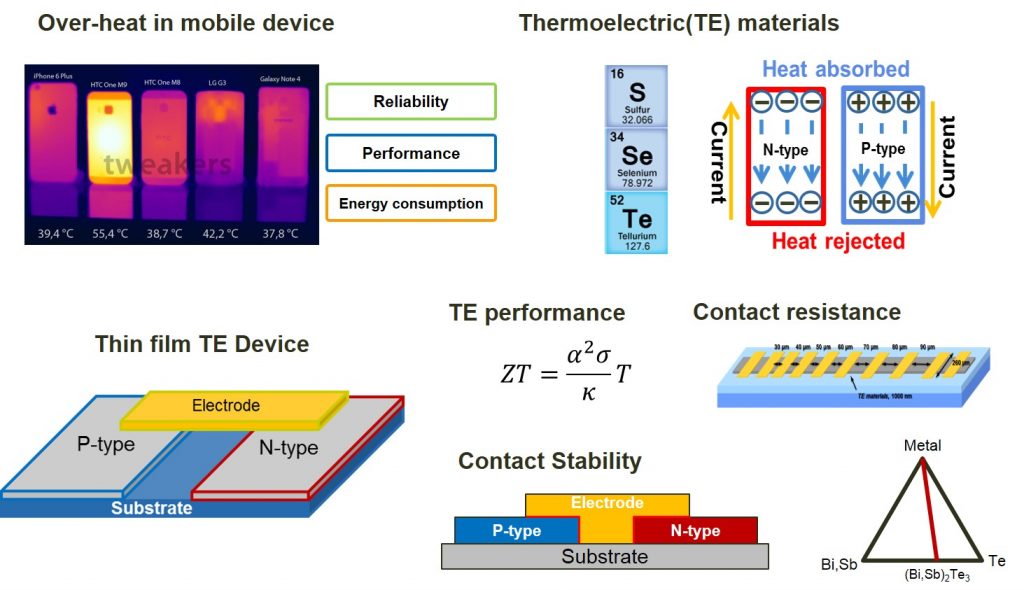

Nowadays, the performance lowering due to over-heat of application processor (AP) is a hot topic in the mobile device industry. The thermoelectric (TE) material will be the proper solution of that problem. Development of TE has been separated bulk and thin film (planar). Due to the limitation of space in apply on AP, planar type of TE will be the best solution using TE. Low dimensional applications need to develop the performance for the lower dimension of thermoelectric. The behaviors of thin film TE materials differ with bulk TE materials due to differences in progress between them. And thin film TE material has yet been studied deeply for new cooling applications of microelectronic devices which includes AP. Therefore, we design the planar type radial structure of TE device for AP cooling focused at the heating area, which can spread out the focused heat horizontally. Because the over-heat problems occur at focused area in the AP.

The performance factors of TE materials is defined as ZT value, which is combination of seebeck coefficient (α), electrical conductivity (σ), temperature (T), and thermal conductivity (κ). These properties of thermoelectric materials have to optimize with their performance at temperature in use. Among the thermoelectric materials, Bi – Sb – Te TE materials are widely used due to their high efficiency at the room temperature. Controlling composition, crystallinity, and nanostructure can be the main strategy for improving properties, related with majority carrier. Therefore, the major carrier properties need to be analyzed with controlling composition, crystallinity, and nanostructure. Based on optimized TE thin film with modifying those factors, we fabricate the TE film for manufacturing planar radial thermoelectric device which can cool down the heat source of AP device.

TE thin film has various deposition method such as evaporator, sputter, PLD and others for using thermoelectric or topological insulator property applications. For those applications, the high quality crystalline phase should be obtained for maximizing its properties.

We fabricate thermoelectric thin film with sputtering system for investigate the performance of thermoelectric properties and fabricate thermoelctric devices with securing electrical, thermal stability of material interface.